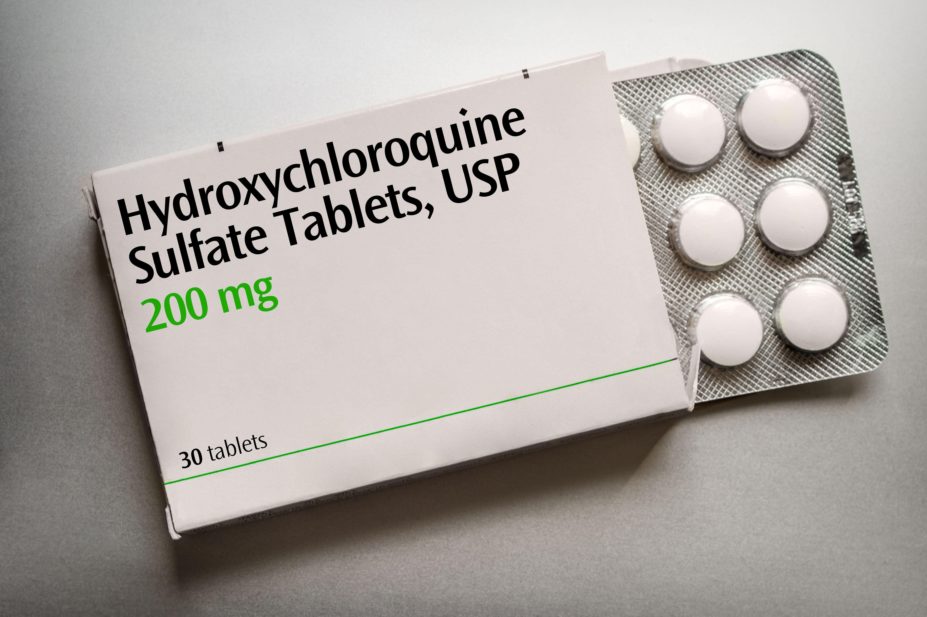

Alamy Stock Photo

Open access article

The Royal Pharmaceutical Society has made this article free to access in order to help healthcare professionals stay informed about an issue of national importance.

To learn more about coronavirus, please visit: https://www.rpharms.com/resources/pharmacy-guides/wuhan-novel-coronavirus

Source: Marc Bruxelle / Alamy Stock Photo

Accord Healthcare said that it plans to produce 60 million hydroxychloroquine tablets using the raw materials it is currently importing to its UK facility

A manufacturer has announced plans to move production of hydroxychloroquine — currently being trialled as a COVID-19 treatment — to the UK from abroad to combat potential shortages.

Generics manufacturer Accord Healthcare told The Pharmaceutical Journal that it was in the process of importing “50 tonnes of raw chemical materials” to its facility in the north east of England, where it plans to produce the active pharmaceutical ingredient (API) hydroxychloroquine.

In a statement, the manufacturer said the imported ingredients will be enough to produce 60 million tablets, which equates to “either 2 million treatments — or in prophylaxis, between approximately 2 million and up to 8 million patient months of supply — based on the various dosing schedules being trialled”.

Hydroxychloroquine, which is used to treat rheumatoid arthritis and lupus, is currently being used in three UK trials across primary, secondary and intensive care.

However, pharmacists have warned that the preliminary results from trials assessing the medicine’s efficacy against COVID-19 should be treated “with care” to avoid patient hoarding and misuse.

Accord Healthcare said it plan to produce an average of 50 million tablets per month from its facility in the UK, by October 2020, which it said is approximately 70% of the UK’s annual use of hydroxychloroquine. The move would also provide “sufficient capacity to supply European markets”.

The manufacturer added that hydroxychloroquine had previously been produced entirely abroad, but that “the API is now being made in the UK”, with some of the raw materials already in the country and others in transport and due to arrive “shortly”.

James Burt, executive vice president of Accord Healthcare, said that if trials around the use of hydroxychloroquine prove successful, “there is likely to be a significant worldwide shortfall in the API”.

Warwick Smith, director general of the British Generic Manufacturers Association (BGMA), told The Pharmaceutical Journal that the Association “welcome the increased capacity and certainty this specific deal will deliver”.

“Currently, around a quarter of all generic prescription medicines dispensed in the UK are manufactured here. While most manufacturers will have significant supplies of API in stock — often six months or more — much of this is sourced from Europe, or further afield in China or India,” he said.

“The current crisis has underlined the benefits, from a medicines resilience perspective, of more robust supply chains and more ingredients readily available.”

The decision from Accord Healthcare comes after generics manufacturers and the BGMA called for European leaders to move drugs manufacturing out of India and China to help stabilise the medicines supply chain.

An investigation by The Pharmaceutical Journal in August 2019 revealed that half of all safety warnings from European and US drug regulators are issued to drug manufacturing sites in India and China, raising concerns over the fragility of the global supply chain.

Sam Roscoe, senior lecturer in operations management at the University of Sussex, raised concerns about fragility in the medicines supply chain when speaking to the House of Commons International Trade Committee on 23 April 2020, suggesting the UK consider “a parallel supply chain where we are able to develop manufacturing capacity to make critical drugs in the UK”.

“The cost will be very high,” he said. “For the majority of generics, there’s not a lot of profit so there will need to be government support.”

He added that a parallel supply chain “doesn’t have to make 100% of the product, it could make 30–40%, but when there’s a crisis, such as a second wave, it is able to ramp up production capacity so that the UK population has the drugs that it needs”.

The UK has already faced supply chain disruptions owing to demand from COVID-19, with pharmacies experiencing difficulties sourcing some commonly used asthma inhalers, while supplies of drugs used when intubating patients with the virus have also depleted.

You may also be interested in

Competition watchdog launches investigation into discontinuation of bipolar drug

Warwick Smith: ‘The pandemic has removed factors that allowed us to be resilient for Brexit’